Your source for quality fasteners

Why we are your source

Wether your products require safety-related parts or not – we deliver precision parts that last. Our focus lays on producting standard or complex fasteners with high quality requirements in small or large series. See yourself what we do to ensure quality.

We offer

- Smallest tolerances

- Production according your PPM or Cpk goal

- APQP / PPAP / IMDS / CAMDS

- Laboratory & Quality Testing Center

- Process stability & SPC-measurement

- ISO 14001:2015 / ISO 9001:2015 / IATF 16949:2016

Nothing is done by chance

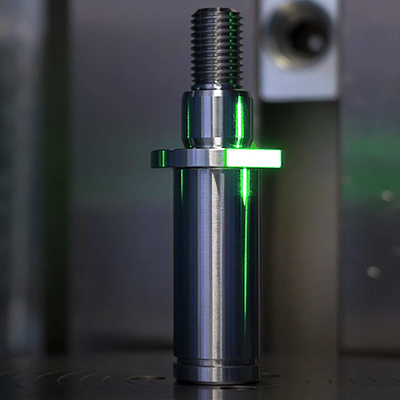

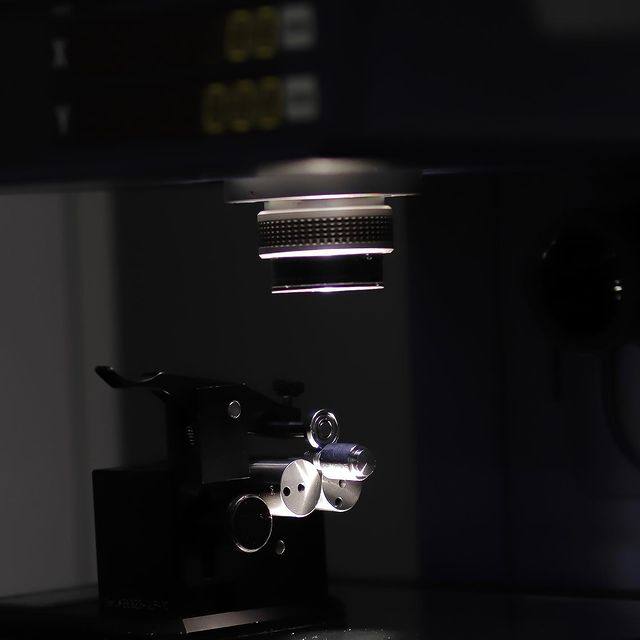

Our Laboratory

Utmost reliability is also ensured at TIGGES by means of our final checks and quality testing. In our own laboratory, we carry out concentricity and 3D-tests as well as micro and macro analyses or grinding probes. Nothing is done by chance, everything exactly planned and problems are solved, not only discussed.

3D measurement ● surface roughness ● hardness testing ● micro- / macro-analysis ● customized tests

The process comes first

Process stability

The process comes in the first place. With our organizational structure we ensure that the production process of your part is always stable, wether it’s your first order or a following one.

- Cpk metrics for every part

- Professional traineed machine operators

- Dedicated SPC-Terminals

- Modern machinary and facilities

- Pre-calculated tooling change

Our specially trained and qualified staff observes the compliance with all defined quality parameters. Before even one part leaves the manufacturing, advanced testing machines and precise processes ensure, that everything meets the customer´s specifications.

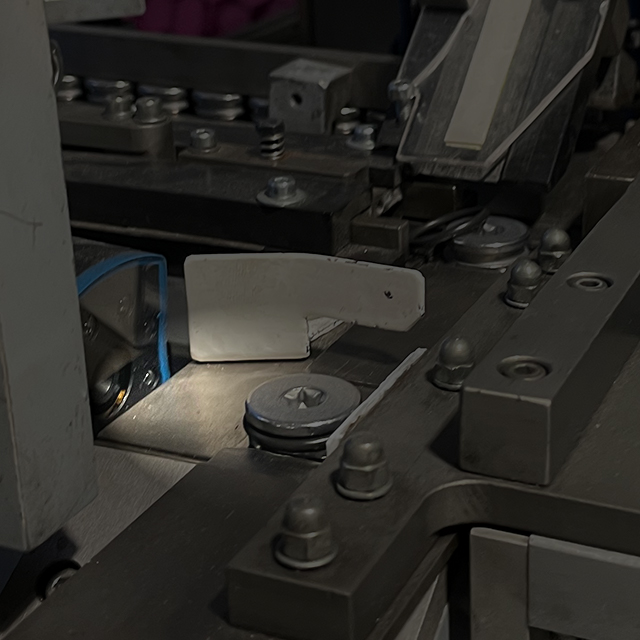

Our Quality Testing Center

Besides special testing machines with highly sensitive camera optics, for instance for automated 360°-controls, and customized test equipments, hand-sorting stations and mounting tables are available for assemblies and processes, which demand real handwork.

Certificates

Every day, our team is committed to ensuring that all the parts you order are delivered on time and meet your quality expectations.

ISO 14000 is a family of standards related to environmental management that exists to help organizations minimize how their operations negatively affect the environment.

ISO/IEC 17025 General requirements for the competence of testing and calibration laboratories.

ISO 9001 is a standard that defines the requirements for a Quality Management System (QMS).

IATF 16949:2016 is a technical specification aimed at the development of a quality management system that fulfills the requirements for the automotive industry.

Quality Reports

Through continuous improvement, we equip ourselves for the challenges of tomorrow.

Product Quality Planning and Control Plan (Advanced Product Quality Planning). The standard set of norms and regulations on which APQP is based: IATF 16949

VDA Volume 2 ”Quality Assurance for Supplies” describes the basic requirements for sampling of serial parts submission for automotive serial parts

Production Part Approval Process. Contains the basic requirements for the sampling of all production and spare parts for the automotive industry according to IATF 16949.

Exchanged between supplier and customer as part of quality management in the event of a complaint.

Supplier information

Our precision parts require a high level of quality - we expect the same from our suppliers.

The Supplier Manual is a binding document. It is part of the contractual agreement between TIGGES GmbH & Co. KG and the supplier and is already valid at the pre-contractual inquiry stage. The German version is binding.

With the supplier self-disclosure we ask you for some basic information about your company. On the basis of the self-disclosure, we will assess the extent to which a further system evaluation on our part (potential analysis) is required in your company.

With the help of this request, defective components are marked.

Any planned deviation must be notified by you using this document.

Our QAA describes the minimum requirements for the supplier’s quality management system and regulates the rights and obligations with regard to quality assurance for the products to be supplied.

This Sustainability Guideline provides what TIGGES expects from our suppliers, in order to act sustainable in the whole supply chain.