Forged parts with mind and technology

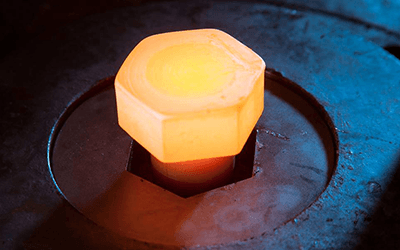

HOT forging

- 5 - 50 mm Diameter

- up to 450 mm length

- powerful spindle presses

- In-house toolmaking

- ISO 14001:2015 / ISO 9001:2015 / IATF 16949:2016

Forged parts from TIGGES

By selective partial heating of the blanks in induction plants, we achieve fast, energy-saving and material-conserving heating of all suitable materials.

High temperature resistant components

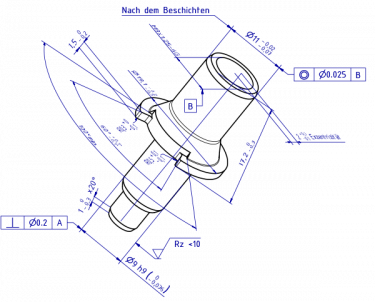

Quality & Dimensional Accuracy

Process stability

Dimensions & tolerances

Material must not suffer, systems must function and connections must deliver what they promise – this is a matter of course for us, even in hot forming.

±0.5 mm

Tolerance

450 mm

Length

5 – 50 mm

Diameter

Standard or special material

Materials

We process all formable materials, such as steel, stainless steel, aluminum alloys, high-temperature steels, titanium, and many more in high-performance spindle presses. Standard or special materials – we manufacture according to your drawing.

Postprocessing &

Finish

Depending on the customer’s requirements, we can finish your hot formed component. We perform a variety of different post-processing and finishing procedures.

Heat treatment

Thread rolling

Thread locks

Coatings

CNC-Machining

Surface treatment

Markings

Advantages of hot forging

Hot forming offers ideal solutions for numerous joining requirements.

- For durable components

- Low forming forces

- High formability

- Wide range of materials

Quality that connects

Send your drawing

We check your drawing and calculate according to the most cost-efficient manufacturing technology your offer

- non-binding

- flexible production possibilities

- experienced designers

All information transmitted is secure and confidential

In-house toolmaking

Even before the actual production, we are active in the factory’s own design and toolmaking. This saves time and effort, as does the subsequent post-processing by machining and thread rolling at TIGGES.

FAQ's

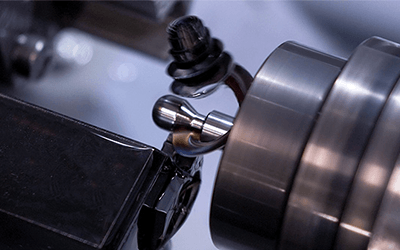

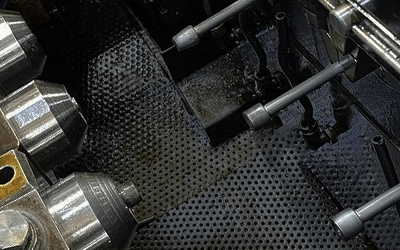

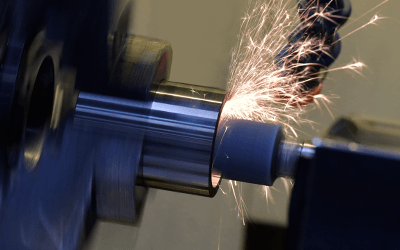

CNC-machining explained

Machining technology is characterized by a high degree of flexibility and precision: Any complex geometry imaginable can be produced.

Machining is also economically feasible for small quantities. The choice of material is not an issue as most metals are machinable.

State-of-the-art CNC machines are required to meet the quality requirements of our customers.

Process of cnc machining

Excess material is removed from the workpiece during machining. Connecting elements can be produced directly by machining.

For particularly high-quality or complex connecting parts, a combination of different machining processes is frequently employed. For example, cold-formed parts are machined in post-processing. These are also known as combination parts. Compared to forming, the material input during machining is significantly higher.

The future of machining

In the future, machining will be fully automated and subject to maximum cycle times. That is why it is important that, in addition to the basic technical requirements, production is also supported by our expertise.

We can already offer automated machining processes today. This enables us to produce flexibly, quickly and with high quality. Our knowledge enables us to optimize existing manufacturing processes and to fully exploit the advantages of machining.