Custom Fasteners for

motorsports industry

Complex part geometries, wide material & capacity range - ISO certified and proven

Motorsports | Reliable precicion parts

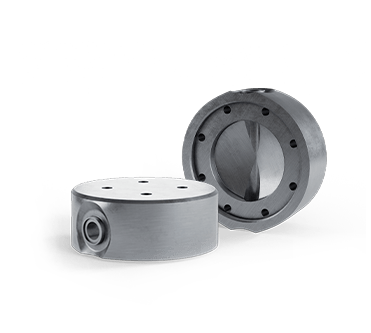

Manufacturing capabilities

Cold forming

Up to 6-stage presses, short throughput times, high dimensional accuracy

- 180 mm

- 2 - 23 mm

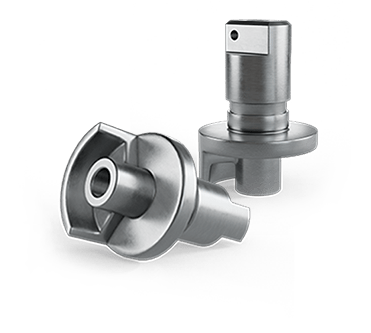

CNC-Machining

Multi-spindle lathes, long and short lathes up to 16 axes, robot inserts

- 1000 mm

- 5 - 65 mm

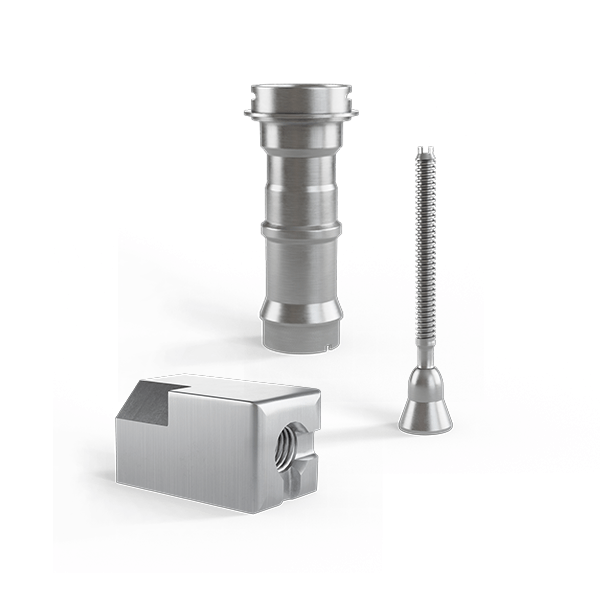

Grinding

High surface quality, dimensional and shape accuracy, with automation

- 1000 mm

- 2 - 350 mm

Process stability

Our top priority is a stable production process. We achieve our goal through experienced machine operators, fixed control loops, pre-determined tool life and regular SPC checks.

Cpk metrics ● Professional machine operators ● SPC-Terminals ● Modern machinary and facilities ● Pre-calculated tooling change

Precision and quality

We manufacture your safety-relevant components that you can rely on. Our production process is based on your PPM specifications. If required, we check every component by 100% inspection, so that not a single one falls outside the specified quality requirements.

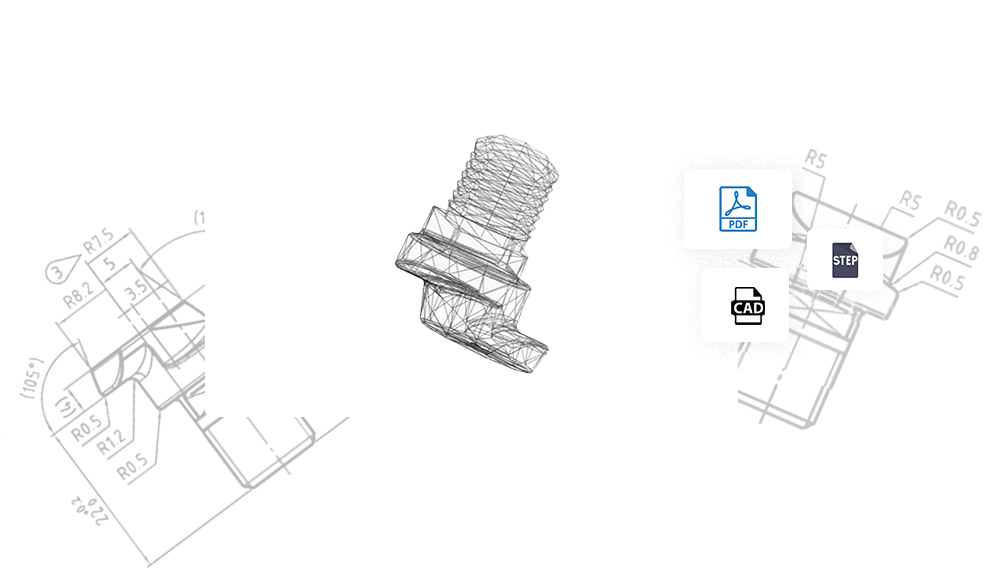

Send your drawing

We check your drawing and calculate according to the most cost-efficient manufacturing technology your offer

- non-binding

- flexible production possibilities

- experienced designers

All information transmitted is secure and confidential