More than just the finishing touch

GRINDING

- 349 mm diameter

- 1000 mm length

- Internal and external grinding

- Dimensional and shape accuracy

- Decorative grinding parts (visible area)

- ISO 14001:2015 / ISO 9001:2015 / IATF 16949:2016

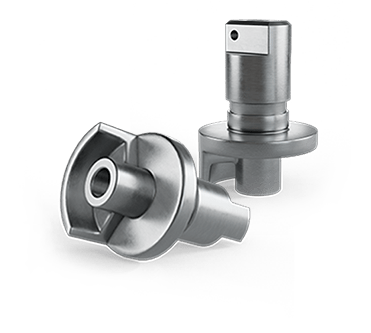

Grinding parts from TIGGES

TIGGES gives your products not only the finishing touch, but also the possibility to implement new ways of production economically.

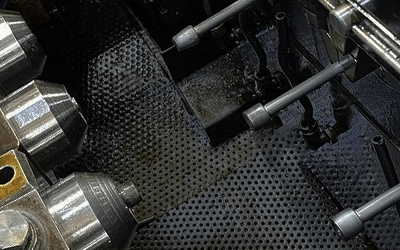

Internal / external grinding

Automation

Quality & Dimensional Accuracy

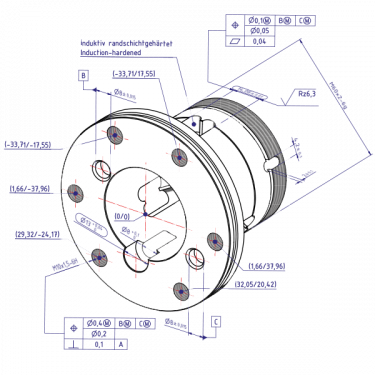

Dimensions and tolerances

In our modern grinding center we manufacture at the highest quality level according to the latest standards of production. Our CNC-universal internal and external grinding machine is the heart of a production, which meets the requirements of today´s products extensively.

10 – 120 mm

Inner diameter

349 mm

Outer diameter

1000 mm

Length

up to IT 3

Accuracy

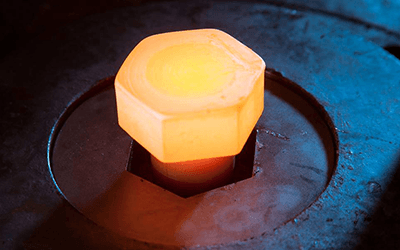

Standard or special material

Materials

We process all grindable materials, such as steel, stainless steel, aluminum alloys, high-temperature steels, titanium, and many more in CNC-universal grinding machines. Standard or special materials – we manufacture according to your drawing.

Postprocessing &

Finish

In addition to grinding, other finishes and post-processing processes can be used depending on customer requirements.

Heat treatment

Thread rolling

Thread locks

Coatings

CNC-Machining

Surface treatment

Markings

Advantages of grinding

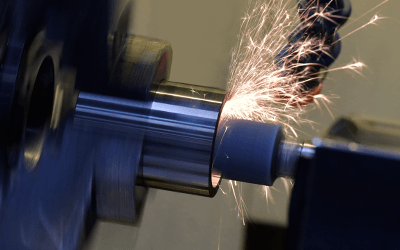

Here, the advantage is the high surface quality as well as the dimensional and shape accuracy, which is in the µm range.

- Perfect finish

- Use in visible areas

- High surface finish

- Good machinability of hard materials

Quality that connects

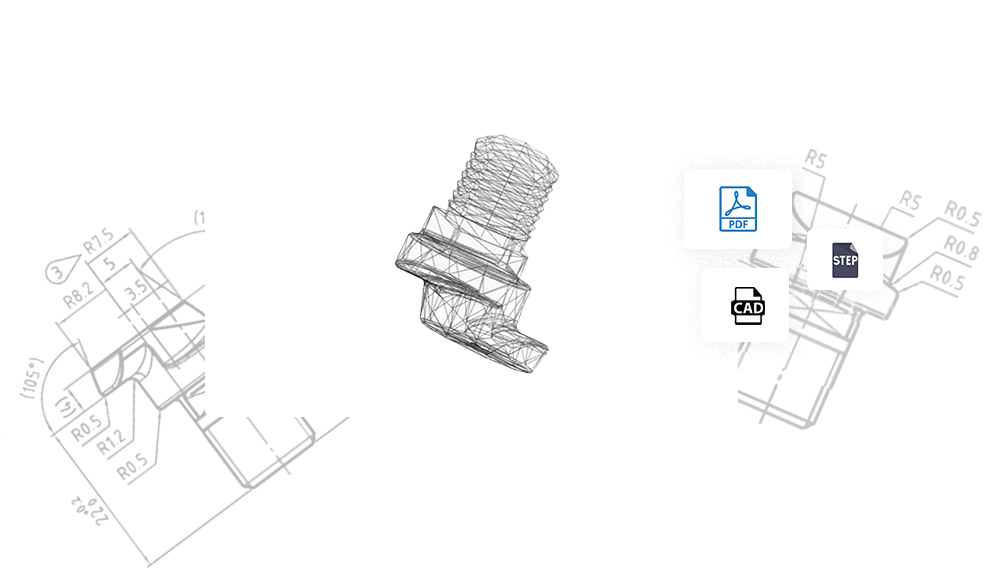

Send your drawing

We check your drawing and calculate according to the most cost-efficient manufacturing technology your offer

- non-binding

- flexible production possibilities

- experienced designers

All information transmitted is secure and confidential

More than just the finishing touch

Depending on the area of application, cylindrical grinding, external grinding or internal grinding is used. We produce special products in small quantities as well as large quantities in series production.

FAQ's

Grinding explained

Grinding is used in the finishing of connecting elements and is an essential component of machining technology. Here, the advantage is the high surface quality as well as the dimensional and shape accuracy, which is in the µm range.

Depending on the area of application, cylindrical grinding, external grinding or internal grinding is used. We produce special products in small quantities as well as large quantities in series production.

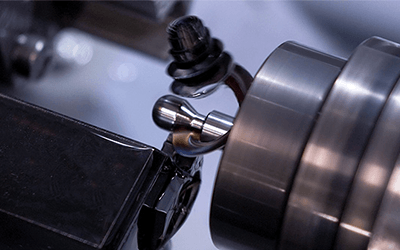

Process of grinding

In the grinding process, the tool and production piece rotate continuously. The grinding wheel removes the metal with the aid of a layer covered with grains.

Our CNC-controlled grinding stations are state-of-the-art to ensure that we are always one step ahead when it comes to quality.

Application for grinded parts

Ground parts are used wherever precision is required. Bearings, seats, valve tappets or sealing surfaces are just a few examples of the areas of application.

Since ground parts also have a visual appeal, they are also used in decorative applications. In sanitary technology, for instance, connecting elements are given finishing touches in order to shine in visible areas.