Part precision perfected by high-tech

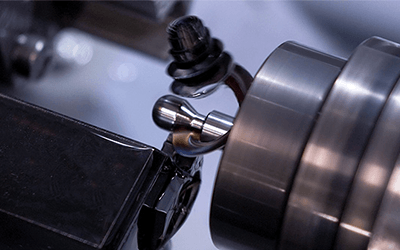

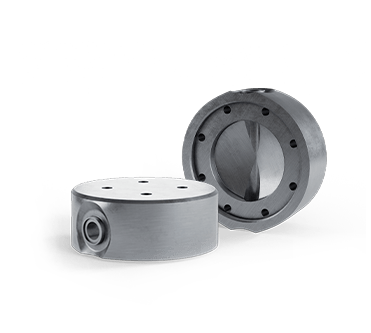

CNC-MACHINING

- 2 - 85 mm shaft diameter

- 700 mm Length

- Manufacturing of complex turned parts

- Automation / Robot inserts

- CNC multi-spindle lathe / long and short lathe

- ISO 14001:2015 / ISO 9001:2015 / IATF 16949:2016

CNC turned parts from TIGGES

We manufacture precision turned parts according to your drawing with a stable process. We act as a development partner and special manufacturer of drawing parts to bring your project to the finish line.

Quality & Dimensional Accuracy

Short throughput times

Process stability

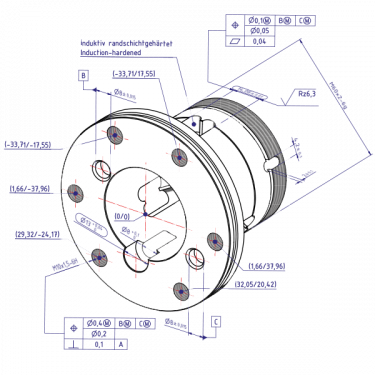

Dimensions and tolerances

Do you need complex turned parts with high quality requirements? Together with you, we clarify the assembly situation at an early stage and highlight the special characteristics of the component. As a result, a TIGGES part fulfills its promise.

± 0.02 mm

Tolerance

700 mm

Length

5 – 85 mm

Diameter

Standard or special material

Werkstoffe

We process all machinable materials, such as steel, stainless steel, aluminum alloys, special steels, titanium, and many more in state-of-the-art CNC machines. Standard or special materials – we manufacture according to your drawing.

Postprocessing &

Finish

The more complex the component, the more often post-processing steps are necessary. We perform a variety of different finshes.

Heat treatment

Thread rolling

Thread locks

Coatings

Grinding

Surface treatment

Markings

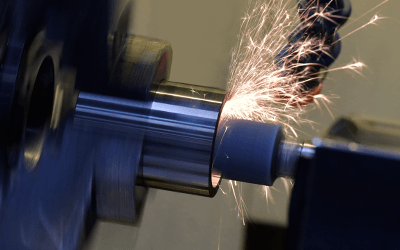

Advantages of CNC machining

Machining technology is characterized by high flexibility and precision in machining: Any complex geometry imaginable can be produced.

- Complex geometries

- Small and large quantities

- Tight dimensional and shape tolerances

- Precise surface structures

- Automation

Quality that connects

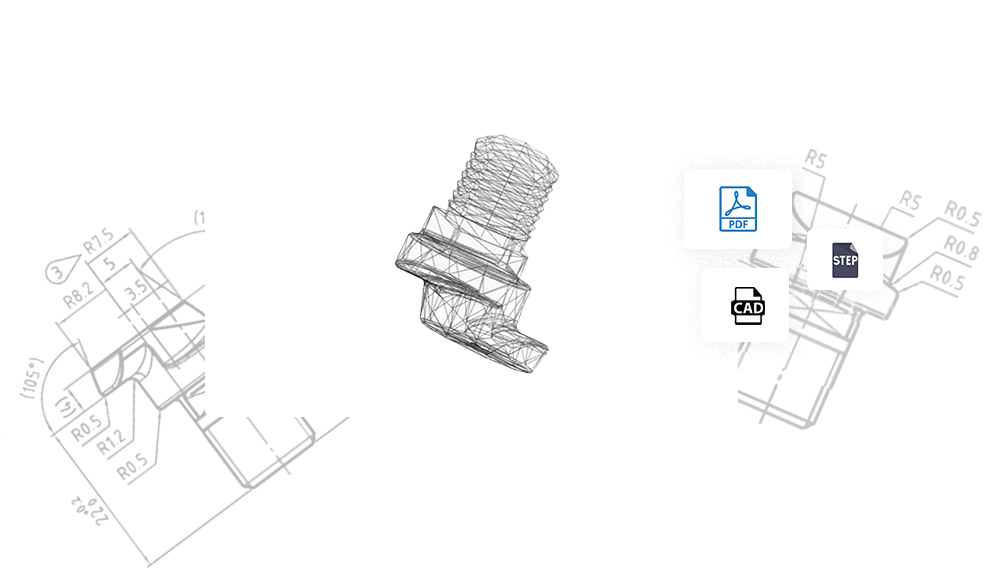

Send your drawing

We check your drawing and calculate according to the most cost-efficient manufacturing technology your offer

- non-binding

- flexible production possibilities

- experienced designers

All information transmitted is secure and confidential

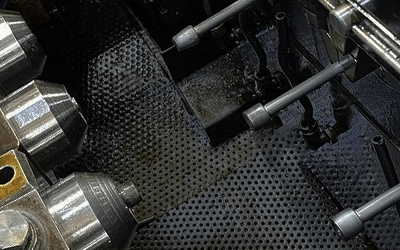

State-of-the-art CNC machine park

Through the combined use of advanced machinery and expert personnel, we push the limits of technological feasibility.

- CNC long and short lathe with up to 16 axes

- Exclusive use of machines with main and counter spindle

- Real machining centers with combined milling/turning operations

- Automation through robot technology

- CNC multispindle machines

FAQ's

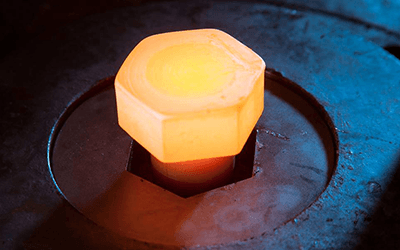

Hot forging explained

Hot forming is particularly suitable for heavy-duty components and materials, e.g. Inconel. During massive forming, only low forming forces are used due to the heat supply. Compared to cold forming, formability is extremely high.

This production technology requires a high energy input. It is important to consider costs and benefits in order to obtain the best possible result from hot forming.

Difference from other forming levels

In forming technology, we distinguish between cold, warm and hot forming. The heat input in the forging process enables the forming of high-strength materials, which is practical for high-strength components.

The temperature during the forming process is variable, depending on the respective type and material. Each material has a different microstructure and requires a specific temperature range.

In cold forming, material consumption is significantly lower due to lubrication or tool loading.