Application in the automotive sector

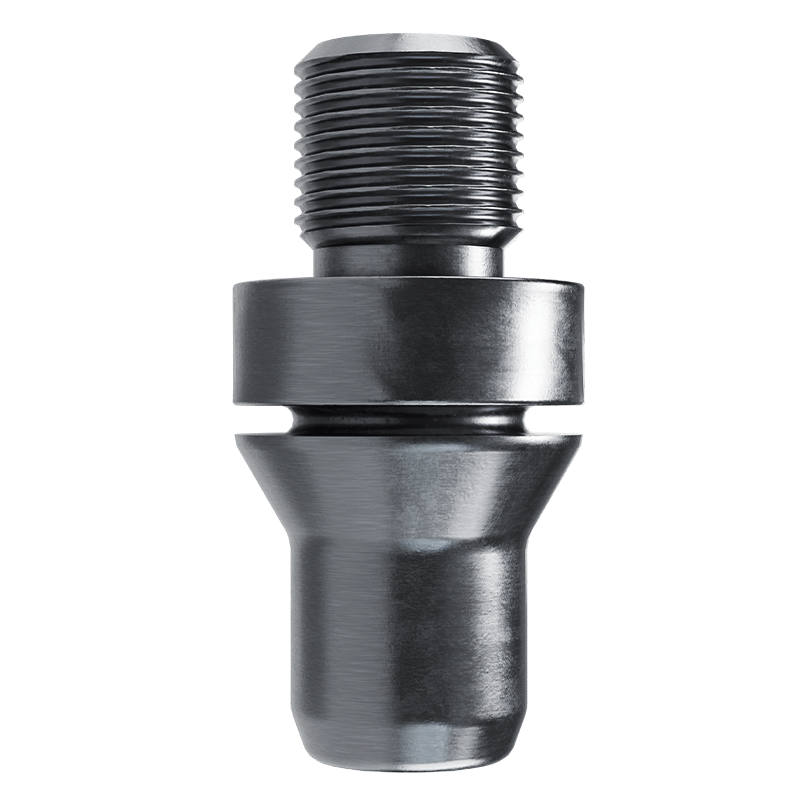

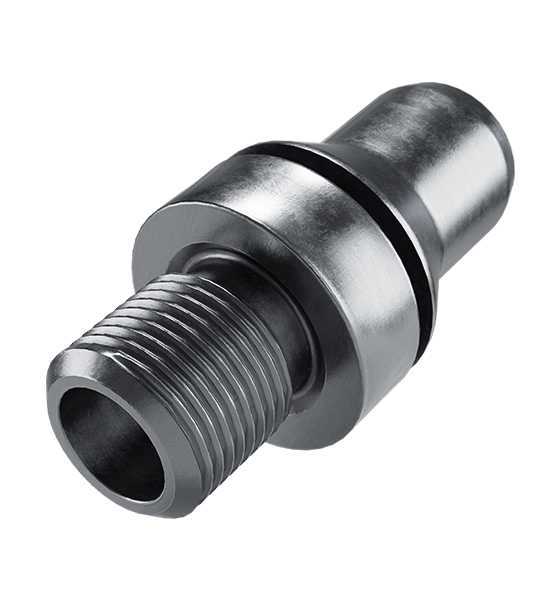

A reliable water and cooling circuit is essential in the engine compartment. Sub-component helps to optimize the bolting situation in the die-cast aluminum housing of cars and trucks.

A combination production process is used here to manufacture the component. First, the blank is produced by multi-stage pressing, in which the connection side is finished in accordance with the drawing. The screw side is then completed in the machining process. The processing of austenitic material poses a challenge here.

80.000 +

Quantity

X3CrNiCu18-9-4

Material

Cold forming / CNC-machining

Technology

Pickling / Passivation

Finish

Our precision parts deliver what they promise. We deliver your quality parts in accordance with your drawings on your desired date.

A reliable water and cooling circuit is essential in the engine compartment. Sub-component helps to optimize the bolting situation in the die-cast aluminum housing of cars and trucks.