December 14 2022

Share

As we all know, there are many different paths to go and different technologies that lead to the production of your component.

Cold forming is no longer the simple pressing of DIN screws as many people know it. Much has changed in technology since then, and it is now possible to press a wide range of geometries with complex materials and tight tolerances.

Find out more about how you can profitably use cold forming for your procurement of complex components.

Cost-effectiveness

- Short cycle times of only a few seconds

- low material consumption

- High process stability

100% COLD PRESSED PARTS

Various geometries cold pressed possible

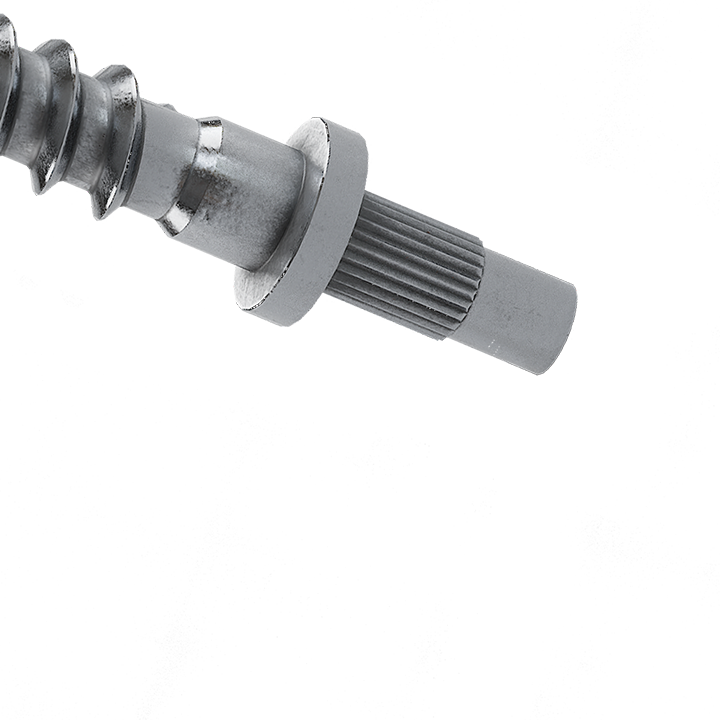

In a wide variety of part projects, we demonstrate the possibilities offered by cold forming.

We are able to press complex geometries with narrow tolerance fields without post-processing.

By converting turned parts into pressed or combined parts and thereby producing them more cost-efficient, we are continuously impressing our customers.

COMBINED PARTS

Post-processing of press blanks

press + cnc-turn

With the post-processing of pressed blanks, it is possible to benefit from the advantages of cold forming without losing maximum precision.

Particularly in the case of high volumes, the advantages are most noticeable due to the production speed. The production of the pressed blanks and the second operations require only a few seconds of cycle time. Automated feeding systems and robotic insertion systems are used for all post processing operations of the components.

Compared to CNC turned parts, which often require several minutes of cycle time per part, the significant cost-effectiveness of combined parts becomes obvious.

The following post-processing operations are possible:

Rolling of threads or knurls

CNC-turning of tight tolerances

CNC-turning of complex geometries

Grinding of surfaces

TIGGES AS A STRATEGIC PARTNER

Your components as 100% pressed part or combined part

With our state-of-the-art machine park, we are focused on manufacturing your complex precision components.

We act as a development partner and specialty fastener manufacturer to get your project to the SOP. In doing so, we use our engineering expertise since 1925 to advise you on how we can produce your component most cost-effectively.

Especially the change from CNC turned parts to combination parts or even to 100% cold pressed parts can mean great cost savings for you.

Feel free to have your components checked for such a changeover by TIGGES free of charge. We will be happy to advise you in order to find the best solution for you.

Get in touch

Cookies Data Protection Imprint