US Custom

Fasteners &

Precision Parts

At TIGGES, we reliably support our customers

with state-of-the-art precision parts

Our sourcing capabilities

What we offer

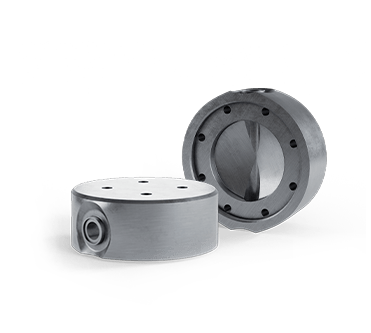

High quality precision parts

The Technical Sales Office, logistics center and plant of TIGGES in Greenville, South Carolina provides a very powerful partner at your side, offering connecting technologies with the quality seal “Made in Germany”.

TIGGES. The Benchmark.

See what challenging projects we accomplished in the past. We are exited for the next one.

Sales Office

Quick support for your purchasing team

Logistic center

One stop shop for all your local & foreign parts

PLANT

Local CNC-production capabilities

- 660 mm

- 5 - 32 mm

US Precision Parts

Connected Worldwide

The technical advice at your premises, and integrated project support provided by qualified specialists with short paths to the German and Asian production facilities guarantee highest efficiency, profitability and short lead times.

Fast, flexible, cost-efficient

Why choose TIGGES

- Wealth of know-how since 1925

- ISO 14001:2015 / ISO 9001:2015 / IATF 16949:2016

- Specialists plan, accompany, optimize and execute the production process

- Local CNC production & worldwide sourcing network

- High precision and standard parts

Trusted by over 16,000+ customers worldwide

US Precision Parts

Request your fastener quotation now

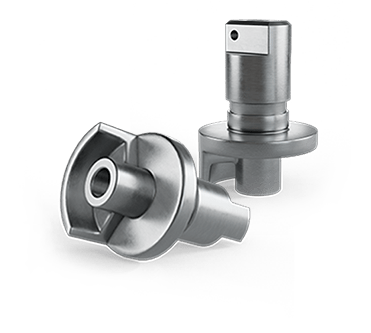

Custom-made, in small and large quantities, from all metals, TIGGES provides, with four manufacturing technologies – cold forming, hot forging, machining and grinding, exactly the connection elements you need. Don´t rely on chance; rely on German quality, precision and professional handling.

Custom Fasteners – your reliable source

Our advantage, we are connected with our own subsidaries in the european and asian market. With TIGGES USA, we support you with your local cnc production. TIGGES Germany serves your needs with the most complex parts and high series productions. In Germany our production facility manages our four technologies cold forming, cnc-turning, hot forging and grinding under one roof. That allows us to produce you custom fastener through different production methods and combine them (combination parts). We figure out whats the most cost efficient production for you. A lot of times cost efficient cold forming is refused cause the part is to complex – but we show you, that the switch from cnc turning to cold forming is possible, maybe. TIGGES Taiwan can deliver cost efficient custom parts with less quality requirements. So wether it’s a standard item or a special item, we deliver the part you need.

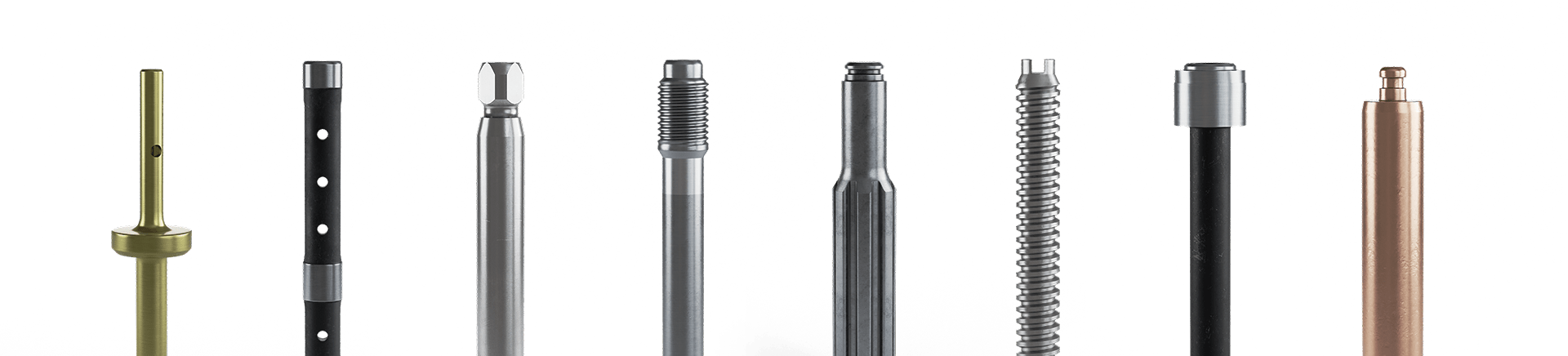

Types of custom fasteners:

- Pins

- Rivets

- Screws

- Socket Products

- Tapping Screws

- Washers

- Bolts

- Knobs

- Inserts

- Locknuts

- Miniature

- Studs

- Hex cap screws

- Carriage bolts

- Hex nuts

- Flange bolts

- Thread forming screws

- Self Drilling screws

- Semi-tubular

- Self tapping screws

- Sems screws

- Plow bolts

Fastener Finishing and post processing

After a part is pressed or turned there are multiple options for value added services. For cold formed parts it’s possible to add a cnc-turning process to reach more complex geometries, that are not possible via cold forming. Often inner and/or outter threads are added for functionality for cold formed parts as well. But there is also the possiblilty to add a heat treatment to increase the hardness of the part, or it is possible to grind the part to ensure a special required surface roughness. For some application a thread-lock or a company specific marking is possible as well.

The performance of a fastener can also be increased with a coating. The range of these is very wide, you can see base applications below.

- Zinc (electroplated)

- Cadmium (electroplated)

- Chromate

- Black Oxide

- Phosphate & Oil

- Color Phosphate

- Iridite

- Nickel

- Hot Dip Zinc (galvanizing)

- Passivating

Custom Bolts and Screws

The most common way to produce bolts is through cold forming. By using cold forming, the shape of the part is achived in a multi-step pressing process. Afterwards, the thread is added by one of the following methods:

- Thread rolling

- Thread Cutting by screw machine

- Thread cutting by cnc lathe

With these different methods a wide range of threads can be produced. Afterwards the parts can be delivered blank or a surface treatment can be added to yours special needs.

Fastener materials

Almost all different kinds of materials can be used to manufacture fasteners. It depends on the individual production process, which material in applicable. The most common tyoes of metals and alloys that are used for fasteners include

- Alloy Steel

- Stainless setel

- Brass

- Bronze

- Copper

- Aluminium

- Titanium

The right choice of material is important for you application,wether your part needs to be withstand heat, requires hardness or is designed for lightweight constructions.

Quality requirements for Custom parts

We at TIGGES have the drive to deliver high quality precision parts that you can rely on. As a supplier for not only standard but also safety-relevant parts, our parts must be flawless and hold what they promise. This commitment to quality is proved in diffent certificates such as ISO 14001:2015, ISO 9001:2015, IATF 16949:2016. We fullfill permanent tolerance checks via all dimension measurement and static process control (SPC) to ensure that the process is stable.

Fasteners in different industries

Most likely, there are parts from TIGGES in your car. Perhaps also in your refrigerator, your window or your shower – our parts can be found in a wide variety of products. Our fasteners are also needed in the industrial sector for example in the construction of water pipes or in medical technology. In general: wherever quality and durability are required.

Order process for TIGGES Fasteners

The order process of TIGGES is simple. You can send your drawing or use our contact form to tell us more about your project. We are also available for you via info@tigges-group.com and +1 864-520-1033. If needed, a NDA can be signed before any important data is shared.

Once you contacted us, your RFQ is going through our awarded workflow system, that allows us to provide a quote within a short period.