Forged qhov chaw nrog lub siab thiab thev naus laus zis

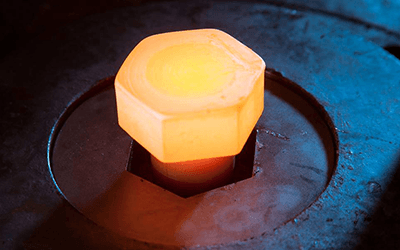

Kub forging

- 5 - 50mm Txoj kab uas hla

- mus txog 450 mm ntev

- haib spindle presses

- Kev tsim khoom hauv tsev

- ISO 14001: 2015 / ISO 9001: 2015 / IATF 16949: 2016

Forged qhov chaw los ntawm TIGGES

Los ntawm kev xaiv ib nrab cua sov ntawm qhov khoob hauv cov nroj tsuag induction, peb ua tiav sai, txuag hluav taws xob thiab txuag cov khoom siv cua sov ntawm txhua yam khoom tsim nyog.

Kub kub resistant Cheebtsam

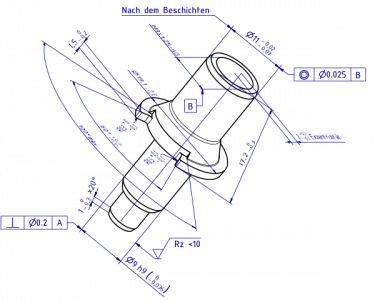

Quality & Dimensional Accuracy

Txheej txheem stability

Dimensions & kam rau ua

Cov khoom siv yuav tsum tsis txhob raug kev txom nyem, cov tshuab yuav tsum ua haujlwm thiab kev sib txuas yuav tsum xa lawv cov lus cog tseg - qhov no yog qhov tseem ceeb rau peb, txawm tias kub kub.

± 0.5 mm

Kam rau ua

450 hli

Length

5 - 50 hli

inch

Txuj lossis khoom tshwj xeeb

ntaub ntawv

Peb ua txhua yam ntaub ntawv tsim, xws li steel, stainless hlau, aluminium alloys, high-temperature steels, titanium, thiab ntau yam ntxiv hauv kev ua haujlwm siab spindle presses. Txheem lossis cov ntaub ntawv tshwj xeeb - peb tsim raws li koj daim duab.

Postprocessing &

Tag

Raws li cov neeg siv khoom xav tau, peb tuaj yeem ua tiav koj cov khoom kub tsim. Peb ua ntau yam sib txawv tom qab ua tiav thiab ua tiav cov txheej txheem.

Tshav kub kho

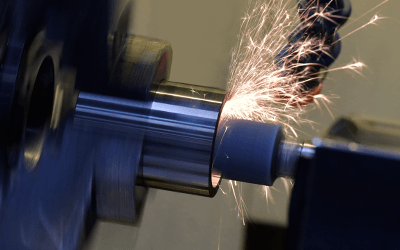

Xov dov

Xov xauv

Kev Siv Lub Tshuab Hloov

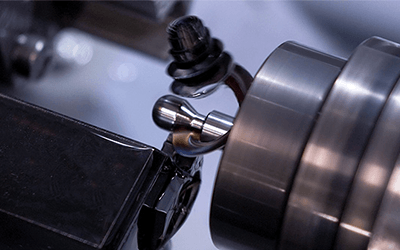

CNC-Machining

Kev kho qhov chaw

Cim

Qhov zoo ntawm kub forging

Kub forming muab cov kev daws teeb meem zoo tshaj plaws rau ntau qhov kev sib koom ua ke.

- Rau cov khoom siv ruaj khov

- Tsawg tsim rog

- High formability

- Ntau yam khoom siv

Zoo uas txuas

Cov txheej txheem kuaj

3D Scans / Micro- & macro Analysis / Hardness Test / thiab lwm yam.

Xa koj daim duab

Peb xyuas koj daim duab thiab xam raws li tus nqi tsim khoom siv tshuab uas koj muab

- tsis khi

- hloov tau ntau lawm possibilities

- muaj kev paub tsim qauv

Tag nrho cov ntaub ntawv xa mus yog ruaj ntseg thiab tsis pub leej twg paub

Kev tsim khoom hauv tsev

Txawm tias ua ntej qhov tseeb ntau lawm, peb muaj kev koom tes hauv lub Hoobkas tsim thiab tsim cov cuab yeej. Qhov no txuag lub sijhawm thiab kev siv zog, ib yam li kev ua haujlwm tom qab los ntawm machining thiab xov dov ntawm TIGGES.

FAQ yog

CNC-machining piav qhia

Machining thev naus laus zis yog tus cwj pwm los ntawm qib siab ntawm kev hloov pauv thiab qhov tseeb: Txhua lub geometry txoj kev xav tuaj yeem tsim tau.

Machining kuj tseem muaj txiaj ntsig zoo rau cov khoom me me. Kev xaiv cov khoom siv tsis yog qhov teeb meem vim tias cov hlau feem ntau yog machinable.

Lub xeev-ntawm-the-art CNC tshuab yuav tsum tau ua kom tau raws li qhov xav tau ntawm peb cov neeg siv khoom.

Txheej txheem ntawm cnc machining

Tshaj dhau cov khoom raug tshem tawm ntawm lub workpiece thaum machining. Cov khoom sib txuas tuaj yeem tsim ncaj qha los ntawm machining.

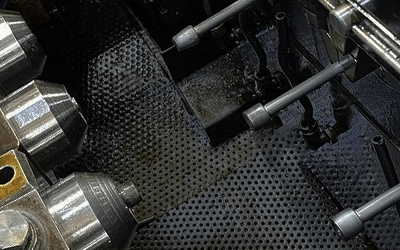

Rau qhov tshwj xeeb zoo lossis cov khoom sib txuas, kev sib txuas ntawm cov txheej txheem sib txawv yog nquag ua haujlwm. Piv txwv li, qhov txias-tsim qhov chaw yog machined nyob rau hauv post-processing. Cov no tseem hu ua qhov sib xyaw ua ke. Piv nrog rau kev tsim, cov khoom siv nkag thaum lub sij hawm machining yog ntau dua.

Lub neej yav tom ntej ntawm machining

Nyob rau hauv lub neej yav tom ntej, machining yuav yog tag nrho automated thiab raug Maximum lub sij hawm voj voog. Tias yog vim li cas nws yog ib qho tseem ceeb uas, ntxiv rau cov kev cai yooj yim, kev tsim khoom kuj tau txais kev txhawb nqa los ntawm peb cov kws tshaj lij.

Peb tuaj yeem muab cov txheej txheem machining automated niaj hnub no. Qhov no ua rau peb tsim tau yooj yim, sai thiab zoo. Peb qhov kev paub ua rau peb ua kom zoo dua cov txheej txheem tsim khoom uas twb muaj lawm thiab siv tag nrho cov txiaj ntsig ntawm machining.

Lwm Cov Haujlwm

CNC-Machining

Multi-spindle lathes, ntev thiab luv lathes mus txog 16 axes, neeg hlau inserts

Txoj kev ua txias

Mus txog 6-theem nias, lub sijhawm luv luv, qhov tseeb qhov tseeb